Product Transform

Contents

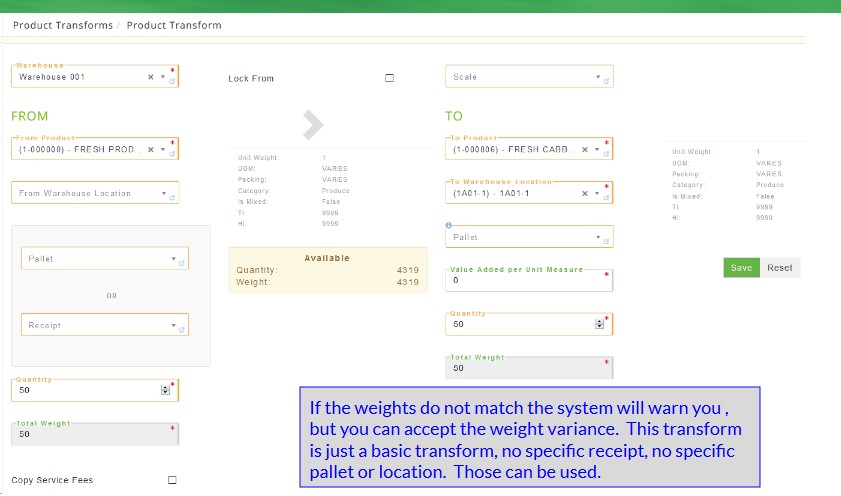

REQUIRED FIELDS FOR PRODUCT TRANSFORM

Warehouse

From Product

Quantity

To Product

To Warehouse Location

Quantity

Process:

Product transform can be used for various reasons.

- To transfer the quantity from one product to another product when repacking salvage/unsorted, etc. into another product. For example, if you received 1000 lbs. of Unsorted Salvage and from that you're sorting out 200 pounds of Asst Dry, or Asst. Dairy or more specific such as Eggs, Bread.

- To break down large cases into units or products or vice versa.

The Transform Product window is divided into two sections: From and To. Explanations for the various fields can be found in the Definitions section of this page. The weight for the FROM and TO normally would be the same. If they vary the system will prompt with a message To/From weights are different. Do you wish to continue to transform wth different weights? For example, 1 case of beans is made up of 20 cans weighing 1/2lb each (10lbs total ) and you will transform that case into 20 individual cans of beans so the weight before and after will still be 10 pounds. For Bar Code users, the From Quantity and/or Weight must be no larger than the Pallet ID or the Location when lookup by location is chosen. Only 1 Pallet ID can be generated for the TO items so the FROM Quantity or Weight should not exceed 1 pallets worth of the TO.

When you select a FROM product you then CAN select a specific warehouse location if you want or leave this blank. (If you use bar coding you will need to use the Pallet or Receipt). If you leave the location BLANK the system will display the TOTAL INVENTORY QUANTITY available whereas if you put in a specific location or specific receipt then the system will display that quantity only.

Complete the required fields and click save.

All fields marked with a * must be completed. Dark grey boxes are view only and cannot be changed.

Field Definitions:

Warehouse * Select the warehouse that the product transform will occur.

FROM

From Product * Select the product reference from the list. The product selected for the From column must have an available quantity.

From Warehouse Location Select the bin location that the product is stored at. This is the location BEFORE the product is moved.

Pallet ID Select the pallet Id where the selected product is located. Bar code users only

Receipt Select from the drop-down box.

Quantity * Enter the amount of the From product that you want to transform to the To product. This amount will be deducted from the current quantity available and a new balance will be calculated.

Total Weight * This field cannot be changed. It is calculated based on the information put in the inventory product detail and the quantity entered in the prior field.

Available Quantity Displays the available quantity from all available logs for this product. Available Weight Displays the available weight from all available logs for this product.

TO

To Product * Select the new product.

To Warehouse Location * Select the bin location that the product will be moved to. This is the location AFTER the product is moved.

Pallet Id Select a pallet or leave blank to let Primarius assign one. Bar code users only

Value Added per Unit Measure * This is the additional cost for repacking the product (boxes, plastic, foam, etc.).

Quantity * Enter the amount of product being made. This amount will be added to the current quantity available.

Total Weight * Under the To column, this displays the quantity of product that will result when it is transformed from the From product.

Important: If the unit of measure for both products is not the same (i.e. one is by pound; the other by case) then the quantities will not match. It is the total weight that should match. If they do not match then you will get an error message. It is up to you to determine if the message is an error or the difference is due to the change in the product’s packaging. If you are repacking salvage and some of the product is waste then you can create an inventory adjustment. Use something such as Spoilage or Waste in the Reason box.

Special Notes:

Before transforming a product you must have a receipt created for the product in which the product will be transformed from. For example, if you receive 1000 lbs of Unsorted Salvage, create a receipt for the 1000 lbs.